Challenge

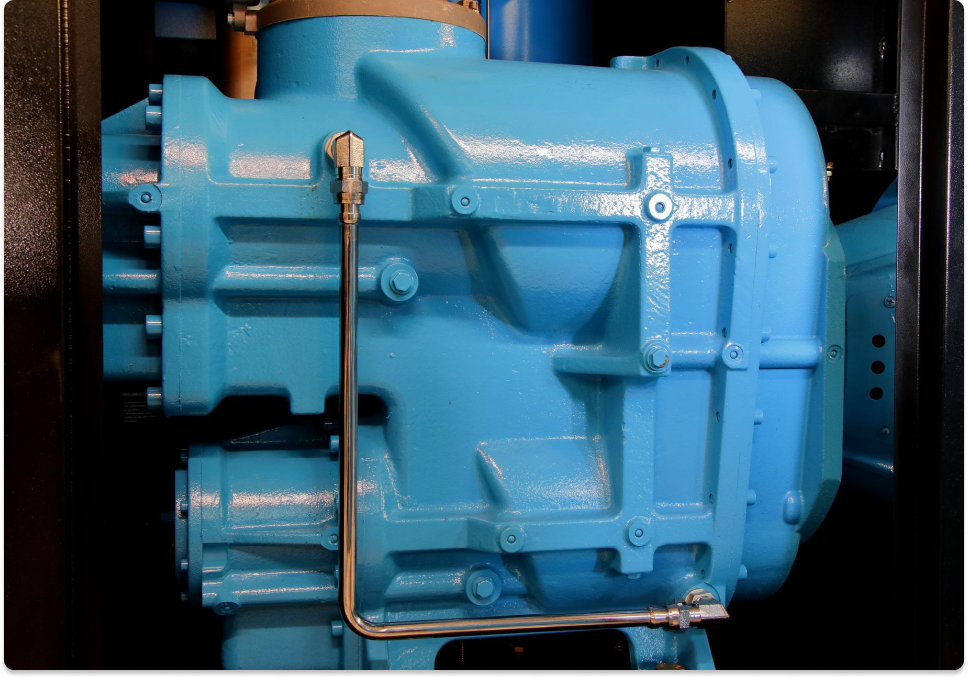

The utility team of a large process industry had the following problems tracking their air compressors

- Very low visibility on how each air compressor is working.

- Unable to determine the actual demand in the plant or when the performance is degrading.

- All the data from the air compressors is physically collected every 24hrs

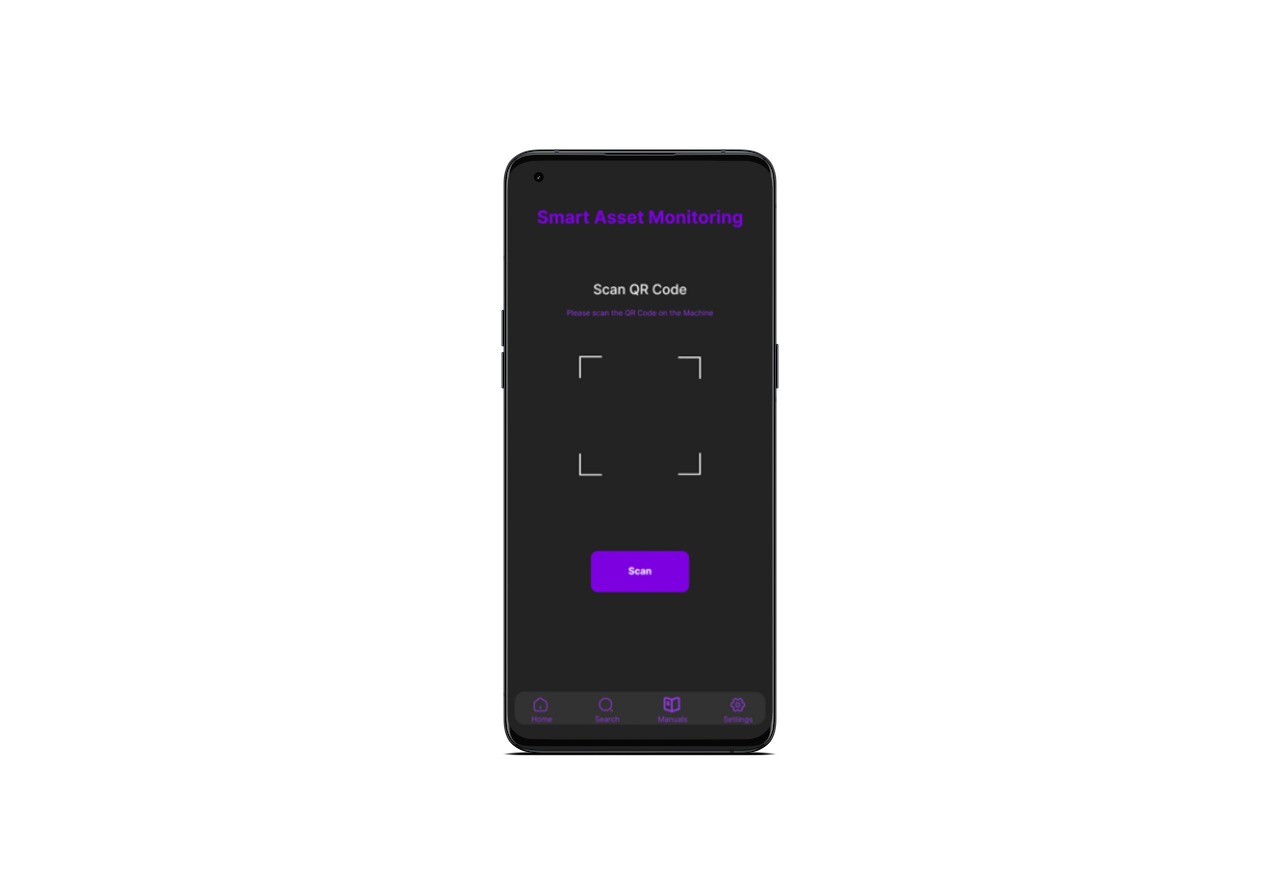

Solution

To monitor in any asset, it must be converted into a smart system. For each asset the procedure for converting the asset into a smart system varies. In this scenario the asset is an air compressor hence the following procedure was used

- Vortex flow meters were installed in all the compressors discharge lines to track the actual air supplied from the air compressors.

- Energy meters integrated with an analytics system was installed in all the air compressors. This helps to deep dive into the compressors energy consumption data.

Impact

Cost Savings

After installation of the asset monitoring system the team was able to optimize the operations of the air compressors which resulted in reducing the power consumption be 5%