Challenge

A large auto manufacturer in India tracked the temperature and humidity levels at various locations in their facility manually.Since the data collected is periodic the client was unable to monitor the variations in the levels resulting in deterioration of electronic components in their storage

Solution

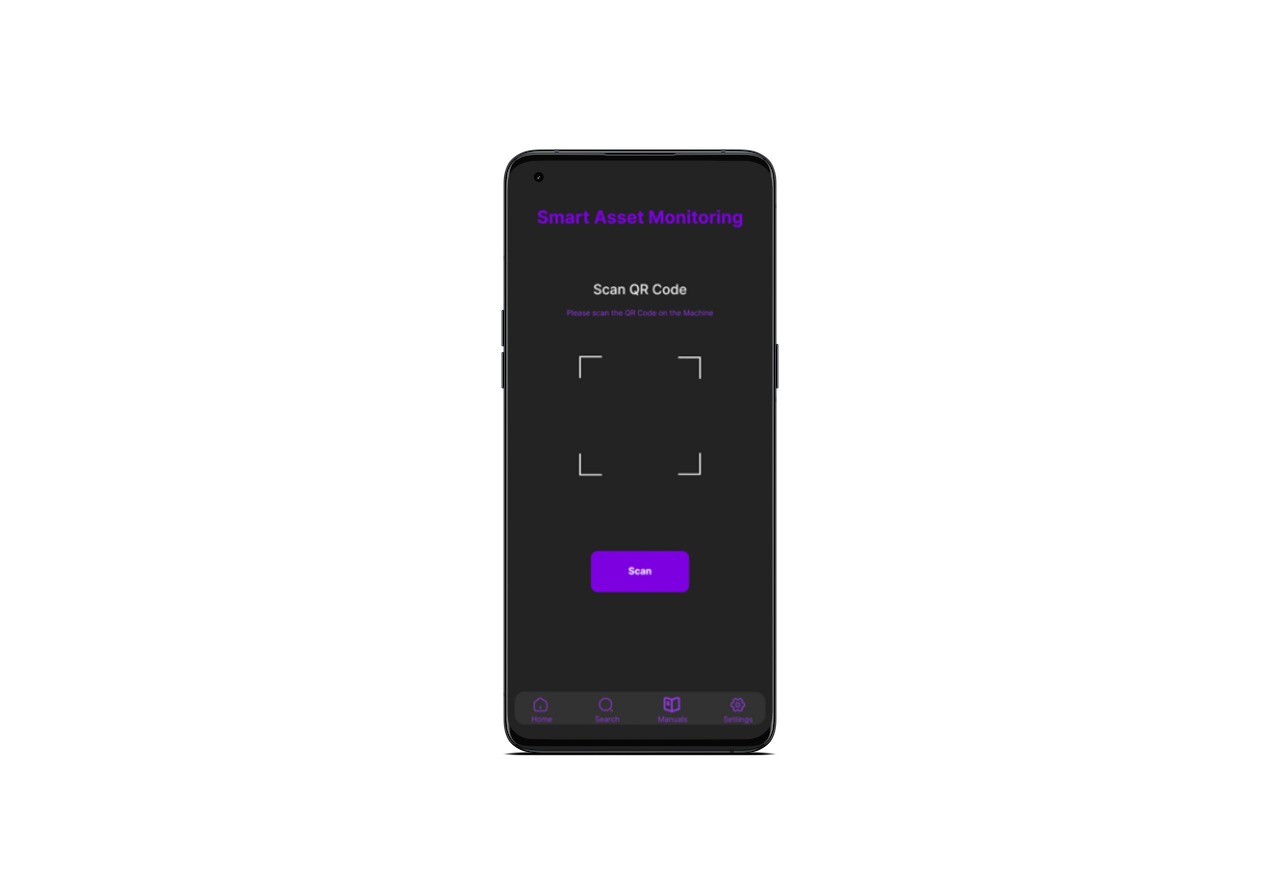

To track the temperature and humidity levels in real-time, wireless IoT modules were installed in all the critical component storage locations. Since these modules were battery powered the installation took less than 15 minutes per installation

Impact

Reduced Imperfections in the material

Electronic component deterioration reduced significantly due to timely action based on the real-time data

Cost Savings

Real-time alerts are sent through emails & Whatsapp to all the end users in-case any of the temperature and humidity levels are out of bounds.