Challenge

A township in India monitored the central and process tanks with the help of operators. This resulted in

- Multiple water overflow

- Increased pumping cost

- Increase in carbon footprint

Solution

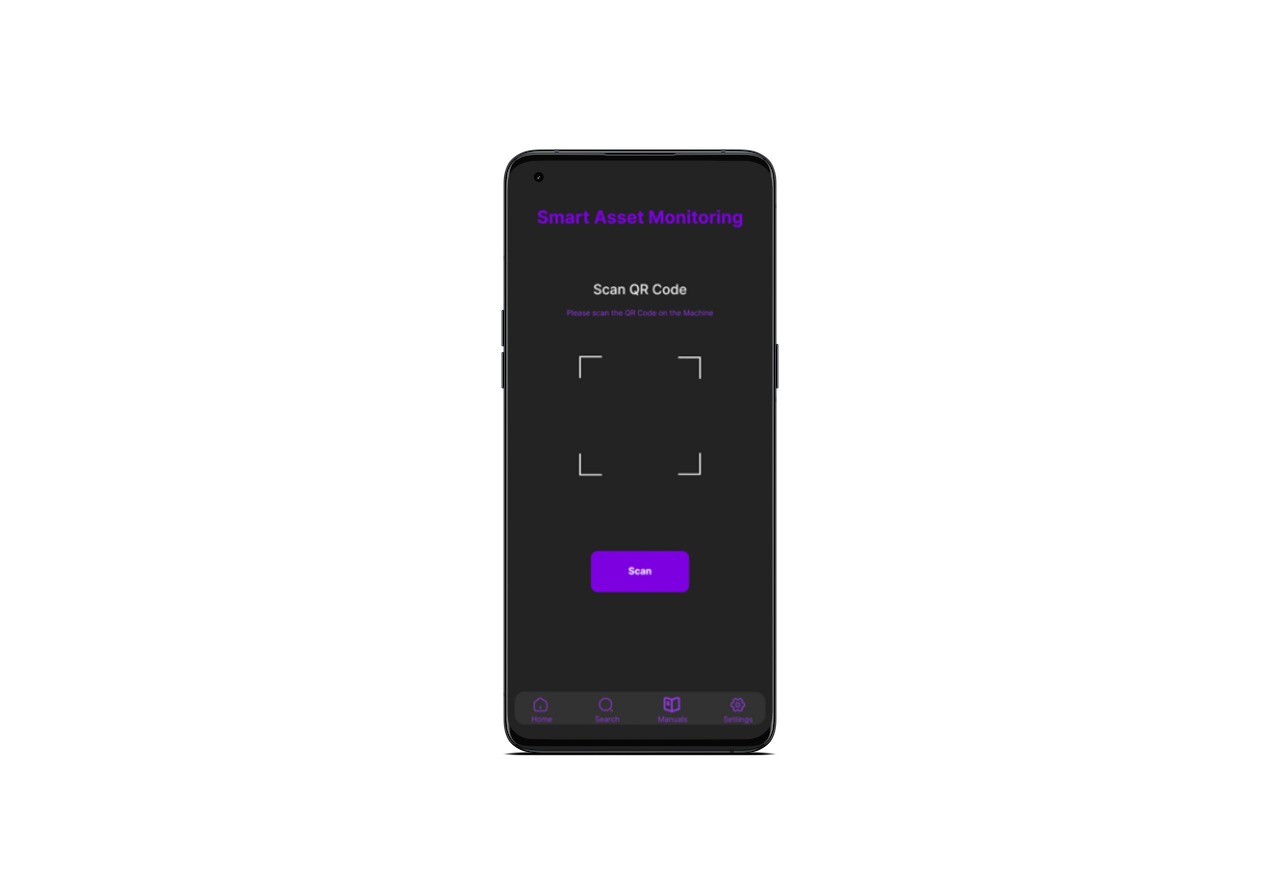

To track the liquid levels in all the storage tanks, battery powered ultrasonic liquid level sensors were installed in all the tanks. The installation for each unit took less than 15 minutes since there is no wiring involved

Impact

Reduced Delay In Fixes

Real-time alerts sent to the operator when the water levels in the tank reach a

dangerously high level.

Cost Savings

- Due to the timely alerts the township is saving 15,000 litres of water everyday.

- On average 12 to 15 Kg of Co2 savings per day in-terms of pumping costs