Challenge

One of India’s largest mining companies faced regular breakdowns and production loss in their refractory unit

Solution

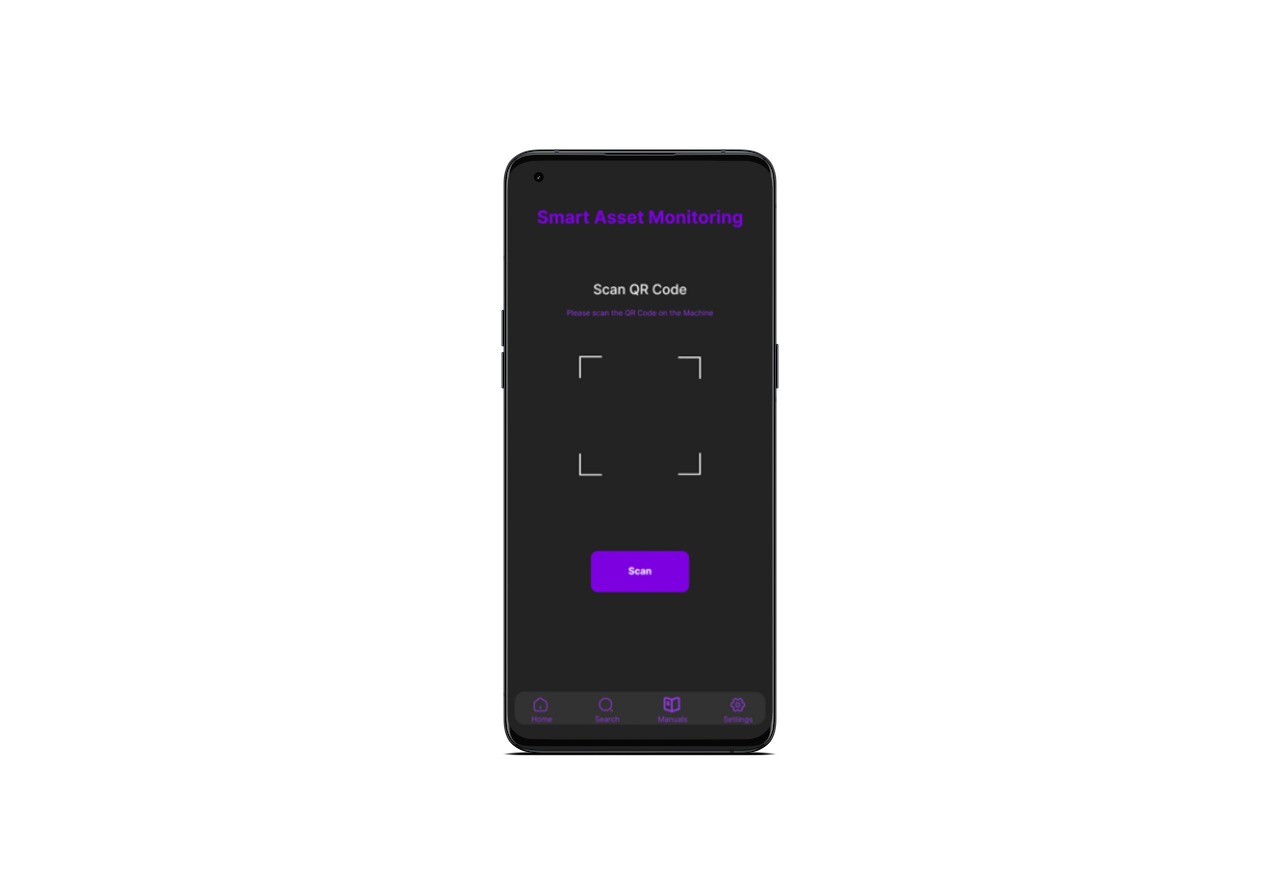

- As a pilot the vibration monitoring modules was installed on 25 types of equipment in the refractory unit.

- Since these modules are battery powered the installation took less than 15 minutes per module.

- The module tracks the real-time temperature and vibrations in all the three axis.

Impact

Reduced Delay In Fixes

- On day-0 of the installation the module detected an increase in vibration in one of the gear boxes and alerted the team.

- The team monitored the gear box closely and scheduled maintenance on day 15.

Cost Savings

- Due to this timely notification the client saved INR 15,00,000 in equipment costs INR 20,00,000 by avoiding production loss

- 10X Return of investment in just 2 months of installation