Enabling smarter factories

Use data from within your factory or facility to deliver sustainable value

SENSOMAK is a technology-driven company! We focus on helping your manufacturing and commercial facilities improve productivity and sustainability through IoT-based digital solutions. Our expertise working in the field and deep shop floor knowledge helps us to understand the challenges facility managers and factories go through.

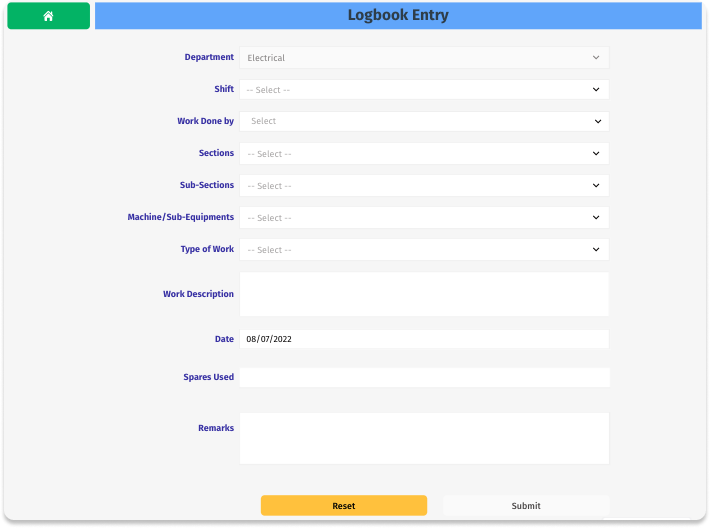

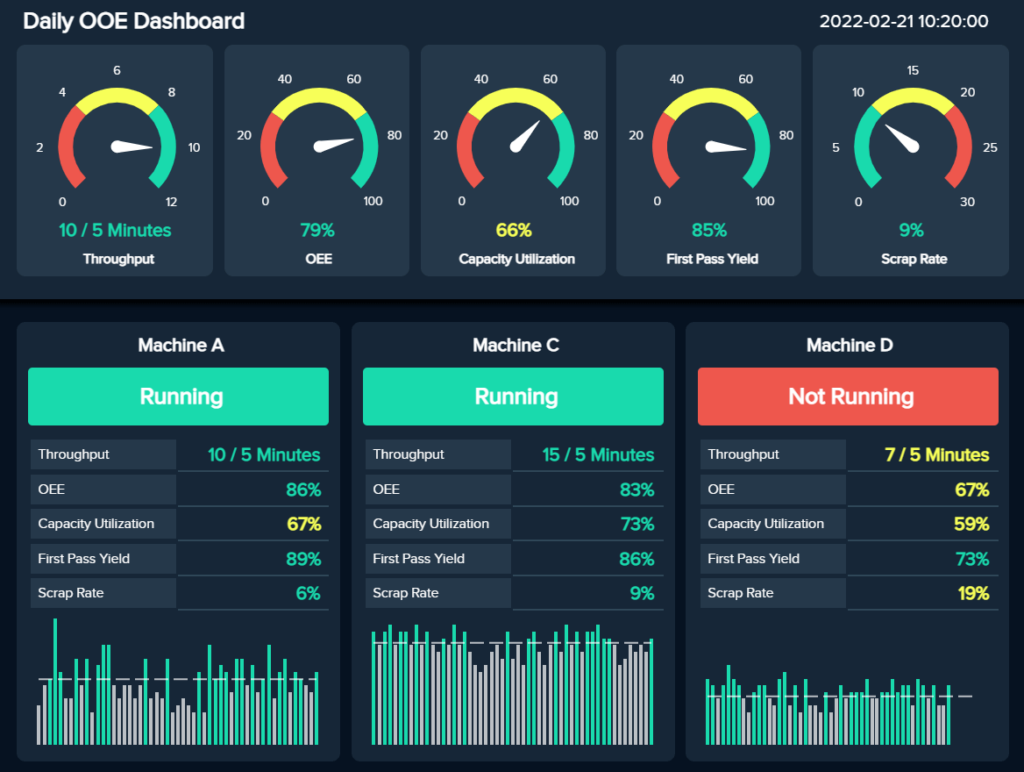

We have designed our IoT solutions and digital products to solve the common challenges faced by your facilities with respect to digitization.

Sensor variety

End-to-End solution

AI/ML based solutions

Access anywhere

Measured savings

Strong engineering team

Our services

What we offer

Enabling smarter factories

We provide you a complete end-to-end offering which not only reduces your head ache nut also drastically lowers your time and cost

Utility Head

Helped us identify multiple leakages and reduce our water consumption by over 15%.

Large Refinery

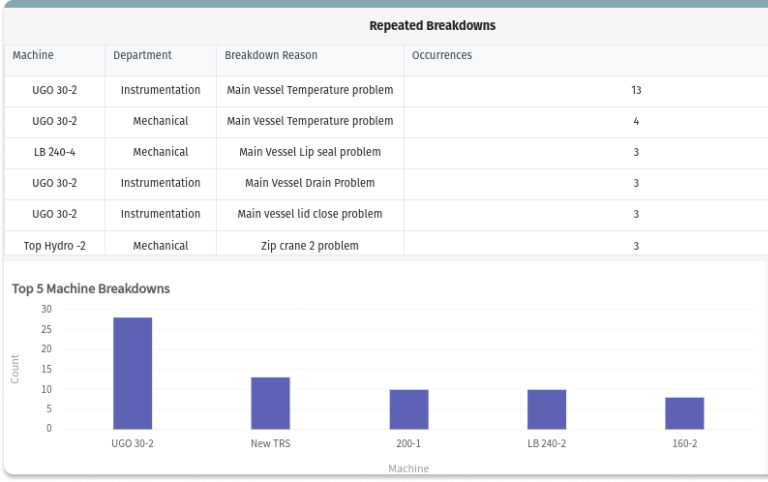

Detected vibration related failures after deploying their smart vibration sensors

Features projects

Our latest projects

Case Study – How an FMCG Identified Leakages By Tracking Compressor Air Flow

Case Study – How IoT Solutions Helped a Process Industry Improve Its Air Compressor Performance